KNOWLEDGE

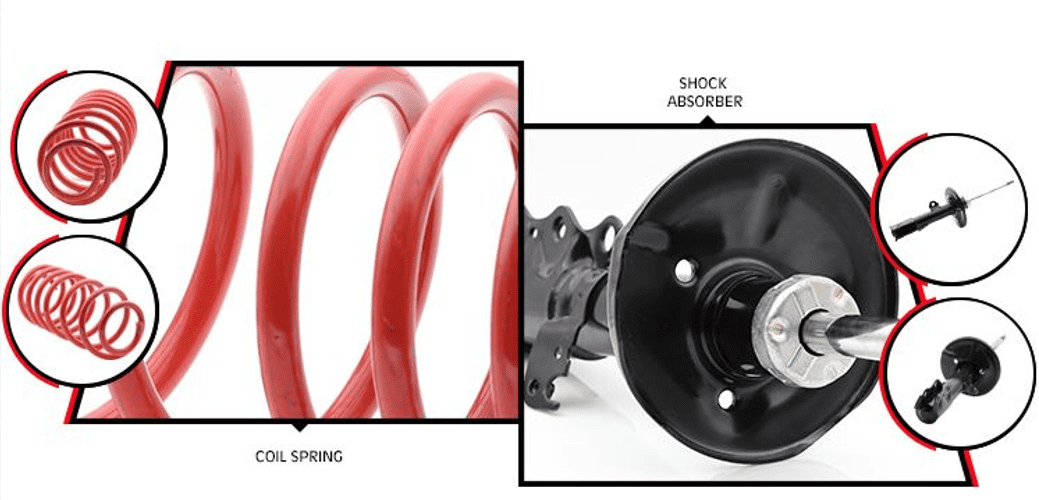

Shock absorbers are designed to absorb or dampen the compression and recovery of springs and suspensions. They control unwanted and excessive spring movements. Shock absorbers keep your tires in constant contact with the road at all times. When you get lost on the road, the suspension and springs of your vehicle move so that the tires can continue to come into contact with the road and absorb energy. Shock absorbers moisturize the movement of springs by converting spring kinetic energy into thermal energy. This thermal energy then decomposes in the hydraulic fluid. The shock absorber is an oil-filled cylinder. As your vehicle suspension moves, the piston moves up and down through the oil-filled cylinder. The movement of the piston up and down forces a small amount of fluid through the hole (small hole) in the piston head. Since only a small amount of fluid is forced out, this slows down the movement of the suspension and dampens compression and spring recovery. Shock absorbers are also sensitive to velocity. This means that the faster the spring moves, the stronger the shock absorber resistance is given.

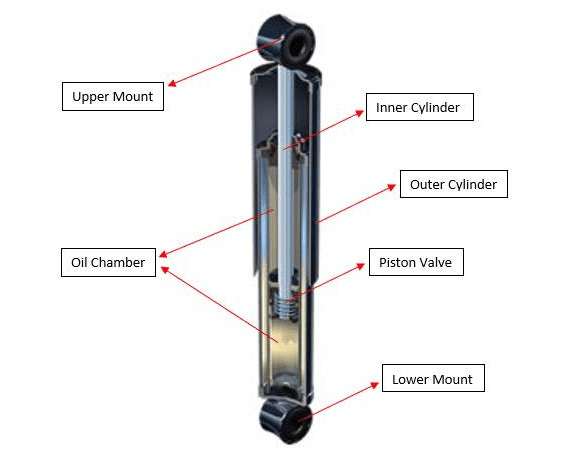

What is Twin- Tube Shock Absorber

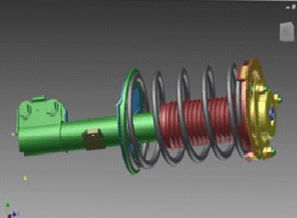

The inner/ working cylinder is where the shaft moves and down. The outer cylinder works as reservoir for the hydraulic fluid. There are fluid valves in the piston and in the stationary base valve. The valve in the piston control most of the damping. The term Gas Shock usually refers to the same twin- tube design, but with one improvement. Low pressure Nitrogen Gas is added to replace any oxygen air. The effect lessens aeration and performance fade.

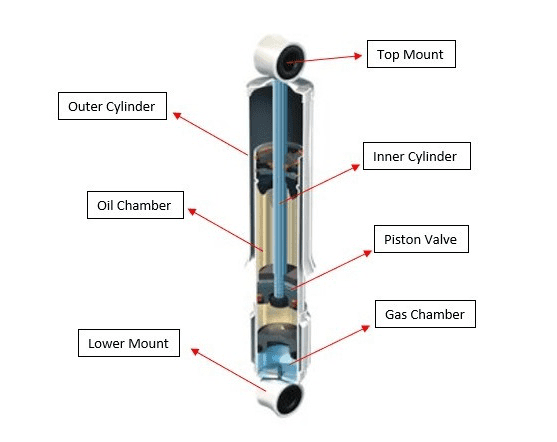

What is Monotube Shock Absorber

The cylinder is divided into sections: A fluid area and a gas chamber. The piston and shaft move in the fluid portion. It uses a single fluid valve assembly in the piston. The diameter of the single working cylinder and piston valve is larger than in a twin- tube even though the outside dimensions of each may be the same. There is no need for an air or gas in the fluid area so the valve can operate more responsively and without any aeration or performance fade. The high- pressure gas chamber is separated from the fluid area by floating piston & seal. It provides an expansion area for the excess fluid movement during the compression stroke. The more aggressive of the movement, the further the floating piston is being pushed into the gas chamber which increases gas pressure quickly and provides additional damping force.

The suspension is there to provide steering stability for good handling and provide a more comfortable ride in all different types of road conditions. Normal suspensions will basically do this for normal driving conditions, such as regular roads and day trips. The sports-adjusted suspension was developed to provide better handling at turns and give drivers a better feel on the road with a lower center of gravity for a more engaging driving experience.

Normal suspension will make any trip feel less turbulent throughout the day driving, while sports-adjusted suspension will allow you to feel the road, as if you were racing on a track. If you plan to drive normally, regular suspension will be fine, but if you plan to drive at high speed in racing style, an adjusted version of the sport may be a better option.

Whatever type of driving you plan most often will be the determining factor of the type of suspension you get. Obviously, this will also affect the type of car you plan.

1.Instability and vibration of steering at highway speeds. Your vehicle never feels completely stable on the highway and is constantly moving up and down. The movement may be slight, but you notice it.

2.Vehicle “tips” to one side in turns. When taking a sharp turn or an off-ramp, your vehicle leans or “tips” to the outside of the turn and feels wobbly.

3.The front-end dives more than expected during hard braking. You may not notice this until you have to jump hard on the brakes.

4.Rear-end squat during acceleration. You’ll notice the front end of your vehicle rising while the rear “squats” during hard acceleration.

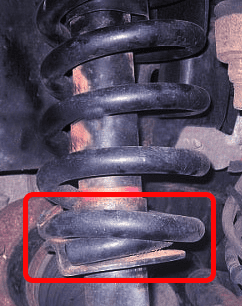

5.Tires bouncing excessively. After hitting a bump, you can feel a tire (or tires) reacting or “bouncing” for a time. You may also hear a clunking noise.

6.Unusual tire wear. Because the tire isn’t being held firmly to the road, the tread wears in a wavy manner instead of evenly.

7.Leaking fluid on the exterior of shocks or struts. This is a sign that the seals have broken and the internal fluids essential to proper function are escaping.

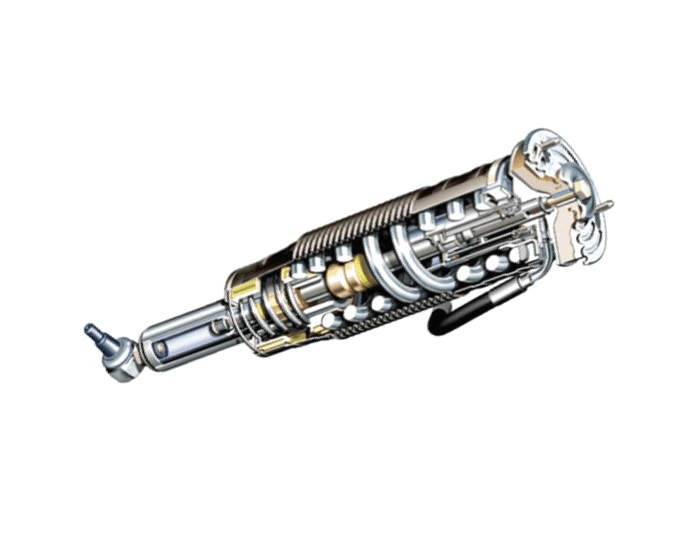

We have more than 35 years of experience in manufacturing shock absorber and coil spring for local and global market. We have full production process of shock absorber and coil spring, including from piston rod machining to outer tube welding, valve system assembly process and also raw material making to final printing of coil spring.